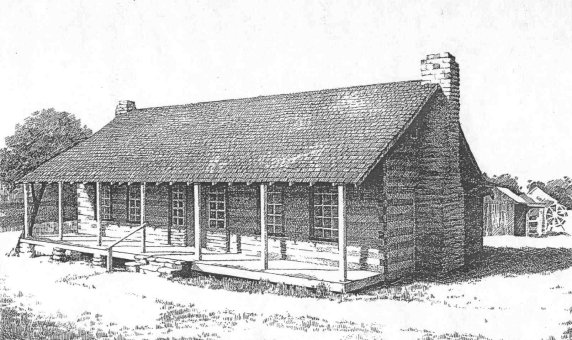

-- illustration by Beverly Austin

Making a Pioneer Roof

When the "Old Gordon House" was moved to Pioneer Village at the White County Fair Grounds, the roof had fallen in and was covered with tar paper for temporary protection. In 1974 the Fair Board decided it was time to have a permanent roof installed. Walter Wisdom, then 81, was one of few men locally who knew how to make a pioneer roof. He was engaged for the job and made all the wooden shakes and nailed them on the roof. The old cabin with the beautiful roof was a favorite subject for artists. But Walter's work didn't last and was replaced by a tin roof in 2007. Walter wrote the following while his work was in progress.

By WALTER E. WISDOM

President, White County Historical Society, 1974-75

In our modern time we have so much building – and large buildings – the roofing industry can supply a variety of materials. The roof today is a simple part of the building. In pioneer days it was very different. Almost all our buildings were covered with hand-riven boards.

Most boards were made from white oak, red oak or cypress timber because these could be split into thin slices and would last many years on the roof before they would rot. We used different lengths of board for different buildings, usually 24 or 36 inches for barns. But for a neat job on houses we would use 16 inches put on in shingle fashion.

There is some skill necessary for marking boards. First there must be a knowledge of timber for the selection of suitable trees for making boards. I gained some knowledge of riving boards at a very early age from my father as I watched him at his work. I have split several thousand boards down through the years but I had not used this skill for several years until the board of directors of the Pioneer Village Museum asked me to make the boards and cover the old log house in this restoration.

Board timber is almost a thing of the past in this part of the country but attorney Ed Lightle owned a tract that had some very good red oak and he donated the trees for making the boards to be used. Trees should be 24 inches in diameter, and not too tough or brash, to split easily with the grain.

After selecting a tree it is cut, then cut into sections 16 inches long and then you are ready for the actual board making. The pioneer used a crosscut saw for felling the three and cutting the sections. The oak blocks are quartered with a wedge driven in with a sledge hammer, then a fro is struck with a wooden mallet to rive off the thin boards. (Cypress boards are made by flitching around the block from the bark to the heart.)

I have rived out enough board for the old log house and will soon have them installed shingle fashion to restore this old building to the same fashion roof it had when it was built about 100 years ago. I have made about 9,000 boards for this job.

Walter Wisdom used primitive tools of the pioneer period to fashion hand-hewn shingles used in reroofing the Gordon House at Pioneer Village in 1974. Walter died in 1988 at age 94. The White County Historical Society is seeking volunteers and donations to maintain and preserve the 19th century complex. For additional information, contact Bill Leach, WCHS, P.O. Box 537, Searcy, AR 72145 or leach@ipa.net