SAWMILLS

Log train and loader, Raney Creek, Ouachita N.F., AR, Caddo River Lumber Company.

In 1845 there was one sawmill assessed in Montgomery County, Arkansas. By 1860 there were four sawmills valued at $8,700 which used raw materials valued at $6,500 employed six persons and paid wages wages totaling $1,260. Lumber produced was valued at $27,350. Small sawmills sprang up all over the county as pioneer homes were being replaced by homes of cut lumber. Cross ties were needed for the railroads so tie hackers came by the dozen. In 1897 the Missouri-Pacific Railroad Company built a line that ran from Gurdon through Clark, Pike and Montgomery counties to meet the needs of the booming timber industries in these areas.

There are 432,000 acres of forest land in Montgomery County, The timber is mostly shortleaf pine, shortleaf hardwood, and mixed upland hardwood. Practically the entire county is in the Ouachita National Forest 287,741 acres being government owned. In 1936 there were six sawmills in the county having the capacities of 1,000 to 19,000 board feet daily. One having the capacity of 20,000 board feet or over and one cooperage plant. 1942 Montgomery County Mt Ida AR WPA History

During the depression many men and youths left their farms and looked for work in the logging camps. The jobs created were important but the environmental impact was huge. Many farms went back to the forest service either being sold or for back taxes. One of the jobs of the Civilian Conservation Corps (CCC) was to reforest the abandoned farm land with pine seedlings. Today sixty-three percent of Montgomery Co. is Ouachita National Forest land. 334,455 acres national forest out of 487,110 acres in county. Total acreage in the county in forest: 432,000. In 1940 there was 287,741 acres in forest. The sawmills were numbered or named for the nearest point of identity. Mills were located near Owley, Gaston Settlement, Manfred and Number Four mill was located at Shady Grove near Mount Ida.

Mill 4

These three photographs were taken at Mill 4 which closed in 1926 and was the last to cut out. Sawmills were usually located near water and consisted of a saw floor and a log deck built about 10 or 12 feet up with a log slip. Ribbons of iron were fastened to the log slip, 'jackladder', and form the track upon which the log car would operate to get the logs up to the second story. The mill was on the Mt. Ida side of Buttermilk Springs with the boarding house right across the road from the mill. Those folks got their mail from Silver. George La Gasse ran the mill and his wife Lessie Awtrey La Gasse was in charge of the commissary there which required folks to pay as they received. There was a church built for interdenominational use. "One Baptist minister was so long winded on Sunday nights that a lot of the congregation would fall asleep and he was a good preacher". When the area was cut out the families would move to the next mill. A stave mill was started up in the same location when big Mill 4 closed.

William Marion Evans [d. Jan 27 1925] sitting with feet inside wagon. Next is Alex Evans son of William Marion. Next is Joseph Edgar "Ed" Evans son of William Marion Evans. Next is William Posey grandson of William Marion Evans and son of Frank Posey. Next with one foot over the side is Frank Posey son in law of William Marion Evans. Photographs of Mill 4 courtesy of Lois Evans. Posted May 3, 2000.

This photo was taken by stacks of the Barrel Staves at Mill Four. Fannie Meeks and Lee Meeks summer1927 with their son born in the summer, August 1926 in a Slab Mill Shack at a Barrel Stave Mill on what is now, Alamo Road, about six miles east of Mt. Ida, Arkansas. Mom said the shack did have a couple windows, but no glass in them, so that winter she soaked some white cloth in lard, or oil of some kind, to let the light through, and nailed the cloth over the windows. They had a wood burning cook stove, they used for heat, and cooking. Said she remembered it snowing, and blowing through the cracks in the walls. Of course she had a Kerosene Lamp, I think this was a one room shack, like so many mill employees built out of Slabs, the waste cut off from logs. Oh yes, water was carried from the near by, Creek, cleaner than any city water of today. There was no paved roads then, gravel all the way to Hot Springs, on the main Hi-way 270. All other roads were farm roads, or logging roads. H. M. Posted Feb. 2006 .

Bates Sawmill Pine Ridge

Walt Bates, Sawmill.

The Bates Sawmill was on the creek at the east edge of Pine Ridge, on the south side of the road. Marion Bates also had a cotton gin there. At other times there was a sawmill about a mile up Hole In The Ground Rd north of Pine Ridge, and another near the church and cemetery west of Pine Ridge. The wood to build the 1st church at that site was cut there. Marion Alexander Bates (1880-1955) married Missouri Jane "Zue" Smith (30 Jan 1883 - 24 Jun 1968) on 16 March, 1902. They are buried at Pine Ridge along with his parents Rev. Ambrose A. and Lucenda "Cindy" Bates and brother Clyde 1910 -1977.

Mr G.L. Graham (1858-1927) from Missouri moved to Mt Ida in 1910 and established a sawmill, planner and lumber company. Yellow pine was processed. Two years later his two sons moved to Mt. Ida. Oscar joined the business and the company was called G.L. Graham and Son. Oscar (1890-1979) ran the business and in 1927 his cousin Lee (1878-1944) became a partner and the business was called Graham Lumber Company. The mill closed in 1944 as the labor pool was non existent as the young men had joined the military and Lee died that year. The mill was on the South Fork north of the Mt Ida P.O. Oscar's son, G.L. Graham, enlisted in the US Army in Oct. 1940, commenced US Air Corps cadet training in August 1941 and got his pilot wings in 1943 and was sent to the European Theatre and became a pilot with the 15th Air Force flying from bases in North Africa and Italy. He was shot down by a German ME-109 on April 23 1944 while in a B-24 on his 21st bombing mission. He was a POW at Stalag Luft 3 and Stalag 7A where he was liberated by an American armoured unit. He returned to Mt Ida in 1945 had became a county judge for eight years. Gordon "G.L." died at the age of 84 in Mt Ida 30 Aug. 2003 and burial was with full military honours performed by Hot Springs VFW Post 2278. He was born Aug. 25 1919 in Montgomery Co. AR. He was the son of Oscar S. and Lela Graham. He worked in the family business while completing high school. "G.L. retired from his business, Graham Pulpwood Company in 1984. Reference: Montgomery County News 4 Sept. 2003.

Black Springs Lumber Company

The Black Springs Lumber Company built a mill at Womble (Norman) in 1907. Rough cut lumber was hauled by mules from the sawmills [sets] in the area to Womble where the planer was situated. This mill proved to be one of the biggest employers in southern Montgomery County until the early 1950s. The above two photographs are courtesy of Shirley A. Manning. Posted 9 May, 2000.

The photo above shows six men on the entrance to a part of the mill at Womble. Thomas Clifton Moore (Clifford) is standing, second from the right and sitting directly below him is William Robert Moore (Rob) who married Irma Lee Miller. Rob's father-in-law Joe Miller was at one time a foreman at the mill. Clifford's uncles Clinton (Clint) and Claude Moore worked at the mill. Some time in the late 30s and early 40s these families moved to California. Photo courtesy of Bill Humble. Posted August 23, 2000.

Jesse Lanier (born 1878) was listed as a sawmill laborer in the 1910 Census for Montgomery Co. AR in Womble.GLOSSARY

Board Foot : A unit of lumber 1 inch thick and 1 foot in length and breadth or the equivalent

Cooperage : The art of making vessels of pieces of wood bound together by hoops.

Crew : Teams. Loggers, yard crew, sawmill crew, planer crew, shop crew.

Crosscut saw : Employed for cutting large trees and other large work. The blades are either curved or straight backs, but the toothed edge is always convex (bulging) and this is what differs them from pit saws which the toothed edge is always straight. The saw ranges from 4' to 10' in length and are operated by two men, one at each handle.

Hardwood : Classification of lumber by source. Hardwood from deciduous trees and softwood from evergreen trees.

Jackladder : Logs were raised to the second floor, log deck, of the mill by a slip.

Millpond : Logs delivered to the mill where stored in water. The fibres were softened, made handling easier and stopped further insect damage.

Millset : Folks who lived at the sawmill camps.

Muleskinners : A teamster. Worked a team of mules.

Skidding : Or yarding. Logs after they were cut to a standard size were hauled to an assembly point, skidway, by mules, oxen or horses. Until 1940 special railroads were used to transport logs from the skidways to the sawmills. Today it is done by truck.

Slab : side pieces of the log with the bark. Waste. Today sent to pulp mills.

Snaking (logging) : a way of moving timber in logging

Stave : The upright pieces for the sides of a barrel are staves.

Wedge : Or undercut is made on the side you want the tree to fall.Mauldin - lumber company town

"The company even printed its own money called 'script' and paid much of its payroll in script which was only good in the company owned store and other business in the 'downtown' area of Mauldin"

Mauldin existed from about 1922 to 1933 and was once a thriving little company town with a company store called the 'Commissionary", business office, church, seven month one-room school, accommodation house, picture show and post office. Located between Pencil Bluff and Mt Ida it was established to house the workers and the mill. The Caddo River Lumber Company had acquired much land in western and northern Montgomery County so built a railroad in 1921 from Womble (Norman) through the Gaston Settlement on the upper South Fork to the future town of Mauldin. The loggers worked together in pairs using cross-cut saws. The logs were hauled the to the hardwood sawmill in Mauldin by teams of mules or by spur engines trains that traveled the railroad spurs that criss-crossed the hills that also hauled the men to the forest for a hard day's work. Pine logs where shipped by steam train to Glenwood and Rosboro mills in Pike County. The old Billy Mauldin house was used to house the first family that moved to the lumber camp. William W. MAULDIN born in ?Greer Co. TX. homesteaded 160 acres 15 October 1906. W 9 2S 25W [North west quarter of section nine in township two south of range twenty-five west of the fifth principal meridian]

"So on as they would get to the new mill site, a house would be started for them. By nightfall, the shanty would be ready for them to move in."

A few people remember living in Mauldin as a small child, swimming in the river, fishing and going to the movies where Willis Willhite was paid to play the banjo while the reels were being changed. Today the land is owned by the United States Forest Service. The mill ponds, that were used to float logs to the mill, were turned into a fish hatchery about 1940. Today the two ponds are a pleasant place to take the boys fishing. At the bottom of Mauldin Mountain, Mt Ida side turn left off Hwy 270 if traveling from Mt Ida on to Mauldin Road and go only two tenths of a mile. A short road leads to the ponds, two one acre ponds. Don't take the nearby forest service road, the ponds are not on that road. The vacant field to the left is were Mauldin use to be. Nothing remains except a few plugged water wells and a few concrete blocks in the forest where the mill stood. The larger buildings at Mauldin were torn down while the smaller houses where moved to Forester, Scott Co. Some Mauldin workers are buried in the Amerson Cemetery to the left of the entrance in unmarked graves. Why? There was only one accidental death at Mauldin. Map

There were superintendents, foremen, engineers and loader operators lived in two-three bedroom homes while the mill workers and loggers lived in smaller two roomed vertical striped pattern board homes built along the railroad and paid $5.00/month rental. The houses were built so they could be moved on flatbed cars. There was a school house and a doctor. Larger families rented two homes and enclosed the area in between. The workers had no job security, health benefits, paid vacation or retirement benefits in the1920s but managed to support their families. After the land was cleared cut The Caddo River Lumber Company sold the majority of the land to the US Forest Service.

Mauldin at one time was the largest town in Montgomery County.

Census in 1930

Population in 1930

Mauldin: 896

Mt. Ida: 512"To name the many individuals who lived and worked at Mauldin would be a difficulty task"

Please email names of Mauldin residents. Thanks. Additional information, photographs, comments are welcome!

I invite you to offer further information on sawmilling in Montgomery County, AR.

Bates, Freeman

Blackmon, Dee Climons & Ella "Veora" & family

Boyd, Hazel & Ras

Brown, Charles Earnest and Ola Mae Flint Brown, Gladys b. Dec. 1923 at Mauldin, AR

Butler, Dr. and family (moved to Lonake)

Carmack, Levi and Silva. Dau Wanda born there in 1932

Carter, William & Onetha nee Metcalf [probably Mitccalf]

Depriest family

Dollar, Frank

Edum, Jim

Gardner, Bill & May

Gaston, Dixie

Gaston, Grady & Anna Fiddler Gaston -

& dau.'s Jean b. 16 Nov. 1929, Norma, Beth, Booth, & sons Inky, Darrel b. 13 Feb. 1927 in Mauldin & Lynn

Hardin, Sam

Dr Harley of Mauldin moved to Hamburg, Arkansas when the mill closed down.

Hipps, Mr. & Mrs.

Hodge, Joe

Howell, James Willie b. 28 July 1929 in Mauldin

Jefferies, Jim & family

Jones, Bill

Jones, Charles "Bay" & Josie Postmistress

Jones, Clerval and Elva Walsh. Charline b. Apr. 1 1931

Jones, Ira & Ella May Tyler nee O'Neal

Kimble, Nellie Postmistress

Kitchens, Bob

Lundry, George & Minnie and large family

McCullar, Joe & Dolly

Marr, Bobbilee

Maxey, Daisy

Maxey, Joe

Maxey, W.T.McKinney, George & Lilly and family

Merchant, John Wiley b. 22 Dec. 1926, s/o John and Edna Merchant

Mullenix, Granville & Bessie

Oliver, John Rowles 1888-1970 (father)

Oliver, Viril Dupree (mother) and children:

Oliver, Archie LeMoyne

Oliver, Billy Joe

Oliver, Mary Alice

Oliver, Wana Dean Oliver (1929-2005)

Peterson, Ed

Price, Otis

Prince, Clifton

Qualls, Rufus & Lydia nee Willhite

Rosenthal, Charlie

Singleton, William and wife Jo. K. Daughter b. 1935 at Mauldin.

Smaling, David and wife Ethel M. nee Bates

Smalling, Roxie & Virgil

Smalling, Minnie & Fletcher

Smith, Dee E. & Mattie Lee and family

Singleton, Warren and Jo Katherin Philpot, dau. JoAn b. at Maulden May 29, 1935.

Story, Loetta, Postmistress

Tidwell, Buck

Welch, Lena & Gus

Wilhite, Alvin and Hazel nee Morrison, son Dale Denver Wilhite b. there in Nov. 1923. Dale's sibs: Mary, Viola, Olen, Darrell, half sisters Juanita and Bonnie, half brothers Audy and Hoyt Wilhite.

Willhite, Willis & Etna and family

Williams, Virgil, Vernon, Carl and Max

Williams, C.H.

Williams, Frank and Lillian. Frank was a machinist at the shop that was located just below the Big pond dam. The family across the road from the shop.

Woodard, Amy PostmistressBorn at Mauldin (WorldConnect) 2015

Brown, Freddie Mae 23 July 1927 Mauldin, Montgomery Co., AR 10 Apr 2002

Father: Charles Ernest Brown Mother: Ola Mae Fant Spouse: Lloyd Eldred Yates

Evans, Carl 27 JUL 1916 Mauldin, Montgomery County, Arkansas

Father: Albert EVANS Mother: Ethel LANE Spouse: Frances Katherine NANTZ

Keenom, Clarence Levi b. 10 Dec. 1925 Mauldin, AR

Kitchens, Erby Lee 3 JUL 1929 Mauldin, Arkansas 25 Dec. 1977

Father: Martin Lee Kitchens Mother: Iva Irsell Martindale Spouse: Lavern Mary StarkJones, Earnesteen born on April 7, 1925 at Mauldin, d/o Ira Jones and Ella May Tyler Jones

Lowdermilk, Martha Sue b. 9 April 1925 Mauldin, Montgomery co., AR

Father: Lilliard Samuel Lowdermilk Mother: Louisa Barbara Jones

New, Venita Joyce b. 18 Feb 1931 Mauldin, Montgomery Co., Arkansas to Oscar and Oma New. She graduated from Acorn High School.

Qualls, Clara 15 Feb. 1929 Mauldin, Montgomery Co., AR

Father: Rufus Qualls Mother: Lydia M. Willhite Spouse: Dee Nathaniel Goss Married: 18 May 1946 in Hot Springs, Garland Co., AR

1920 Census Rufus was widowed, living with his cousin William Nathan Qualls and family in Gaston twsp.

Rufus died 19 Sept. 1956 in Oden, Montgomery Co., AR, buried Brushy Cem.

Vincent, Mac Daniel Jr. b. 29 Sep 1926 Mauldin, Montgomery, AR

Father: Mac Daniel Sr. Vincent b. 13 Apr 1903 in Oden, Mont., AR Mother: Myrtle Henryetta Herron

James Arron "Squeak" Welch b. 25 March 1927 in Mauldin, Montgomery County, Arkansas

died 25 Sept. 1990. Buried Bear Creek Cemetery, Kirby, Pike County, AR

Father: John Augustus "Big Gus" Welch b: 23 Dec. 1897 in Rock Creek, Pike Co. AR

Mother: Elvie I. Yeargan b: 1 APR 1898

Workman, Hattie Bell b. 4 Jan 1927 Mauldin, Montgomery Co, Arkansas

Father: Francis W Workman Mother: Abbie Irene WelchLois Abernathy, age 80, of Royal, died Saturday, July 25, 2009. She was born on May 6, 1929, at Mauldin, Arkansas, the daughter of Ray Carmack and Nannie Goodner Carmack. She was preceded in death by her mother and father; one brother, David Carmack; and one sister-in-law, Joyce Carmack. She was Baptist in faith and was a 1959 graduate of St. Joseph's School of Nursing. She had the distinction of being the first married student ever accepted to the nursing school. She was a retired Registered Nurse, who dedicated her career and life to caring for others. Graveside services held at 10:00 AM, Tuesday, July 28, 2009, at Mt. Olive Cemetery in Oden, Arkansas, with Bro. Larry Catcher officiating, under the direction of Davis-Smith Funeral Home, Hot Springs.

Died at Mauldin, Arkansas

Boyd, Tom ABT 1935 Mauldin, Arkansas

Goodner, Billy Gerald b. 21 Oct. 1929 Montgomery Co, AR 1931 Mauldin, Montgomery Co, AR

Father: Elmer Goodner Mother: Fannie Victoria Holliday

Gross, Nathen Edgar 17 Oct. 1924 3 JAN 1926 Mauldin, Arkansas

Father: William Edgar Gross Mother: Bertha Mae Storms

HATTON, Lou Rache b, 11 Oct 1874 Cedar Springs, Cedar Co., MO 17

Died Jan 1914 Mauldin, Montgomery Co., AR Spouse: John Berry ELDER

New, Othell Edward 13 Jul 1929 Mauldin, AR 13 Jul 1929 Mauldin, AR

Father: Oscar Edward New Mother: Oma L Heath

Robbards, Sarah Ann b. 8 May 1854 Mt. Ida, Arkansas

Died 24 July 1929 Mauldin, Montgomery County, Arkansas

Father: W. J. Robbards Mother: Ellen A. Powell Spouse: Uel Hulbert Edom

SPRIGGS, Elijah b. 3 Aug. 1823 SC d. 1906 Mauldin, Montgomery Co., Arkansas [year does not match]

Father: Gilead SPRIGGS Mother: Sarah UNKNOWN Spouse: Elizabeth WALKER

STEPHENS, Melba Sue b. 3 Jan. 1921, AR d. 21 Feb. 1924 Mauldin, AR

Father: Leonard B STEPHENS Mother: Edna Cornelia Thompson HOLLINGSWORTH

Weddings consummated by County Clerk George Watkins, Mt. Ida in June 1924

Rufus Quals, Oden to Liddie Wilhite, Oden

William Hickey, Mauldin to Wilma Sandlin Mt. Ida.

LINKS

Geographic Names Information System

The Pencil Bluff Sawmill in the 1980s.

Today in the county the forest is an important resource for recreation and employment. The US Forest Service employees many in the county. There are still sawmills about and other related businesses. The C & D Post Co. Inc at Pencil Bluff began in 1992 and make posts from yellow pine. No longer in business.

REFERENCES

- Montgomery County: Our Heritage

- Inventory of the County Archives of Montgomery County, AR (Mt Ida) prepared by the Arkansas Historical Records Survey, April 1942, Division of Community Services Programs, W.P.A.

SUGGESTED READING

- Montgomery County: Our Heritage Vol.1

Back in print. review

Sawmill by Kenneth L. Smith. Sawmill is a history of logging in the Ouachita Mountains of Arkansas and Oklahoma from 1900 to 1950. It is a social history in its account of the lumbermen's quest for the last virgin timber and the effects of its depletion. Kenneth L. Smith interviewed more than three hundred people to develop this history of the cutting of virgin shortleaf pine forests. The recollections included here provide insight into a population that lived through the Depression years in isolated mountain communities. Many photographs. The Caddo River Lumber Company and the Arkansas mill towns of Rosboro, Glenwood, and Forester provided jobs and homes for many during the brief heyday of the big sawmills. 246 pages, map. March 2006 (Originally published 1986, 246 pages) 260 pages, 100 wonderful collection of photographs of that lost way of life, index, 7" x 10" The University Press of Arkansas. A wonderful collection of photographs of that lost way of life. There is a section on the Mauldin sawmill with pictures and a foldout map of the Ouachita Mountains and an entire chapter devoted to Forester.Smith, Kenneth, Timberrrr! Iron horses, iron men: the last of the red hot loggers

Abstract the timber industry in the Ouachita Mountains during the 1930s

Publication Arkansas Times 7(6):56-62, 64 Feb 1981

Illustration photos

Subject Ouachita Mountains, Logging, Lumbermen

Location: Garland County ; Scott County ; Montgomery County- The Mountain Signal April 1999 issue and several issues after that covered sawmills and railroads in Montgomery County

Every year in late September there is a circular in the "Glenwood Herald" informing the community about the upcoming 'Caddo River Sawmill Days Festival' and often includes a historical note. The 'Sawmill Days' event started in 1990 as a fund raiser to move an old train depot which at one time was in Glenwood but had been moved to a farm to be used as a hay barn. The owner gave it to the town if they would raise the money to get it moved. It was moved 1999, but is still under renovation for a possible museum. During the festival several logging demonstrations are held and timber equipment companies present displays. There is a chain saw contest and a log weight contest and a contest to guess the weight of a log truck in addition to the arts and crafts and the kiddy sawdust scramble. In the early 1900s the area was covered in forests. Sawmills came with A.L. Clark constructing a large mill that was later sold to T.W. Rosborough. A railroad and spurs were built to haul timber to the mill and boosted the growth of the region. Today the sawmill in Glenwood is still going full blast. Georgia-Pacific sold the mill to the Curt Bean Lumber Co. which went bankrupt in 2010. The mill was the largest employer in the area.

Woody, Velma B. Branscum: Bandits, Bears, and Backaches : A Collection of Short Stories Based on Arkansas History 2004 Butler Center Publication. Chapter IX Timber: Living and Working in an Arkansas Forest. This fictionalized account's setting is the Ouachita Mountain area in the 1930's. The short story's main characters are the sons of a logging family who worked for the Caddo River Lumber Company. The story describes the processes employed by the Caddo River Lumber Company for moving the families of their workers from one lumber camp to another.

Clear-cutting battle fought in Ouachita National Forest by Kenneth C. Danforth, Rural Arkansas 41(7):6-7 May 1987

Arkansas Business 22 November 1993

Pg. 38 The railroad with the most Arkansas short lines is the Arkansas Midland. The company has four branches around the state that connect with Union Pacific. The branches include Helena, Hot Springs and Norman (Montgomery County). Arkansas Midland is examining the idea of abandoning its Carlisle branch railroad because of low shipping demand.

Obituary Davis-Smith Funeral Home - Glenwood

Curt Bean January 1, 1940 - July 21, 2021

Curt Bean, age 81, of Amity, passed away on Wednesday, July 21, 2021.

He was born on January 1, 1940, in the Centeridge Community (Amity), the son of Johnnie Bean, Sr. and Roxie Garner Bean. On December 8, 1958, he married his sweetie, Jane Carolyn Raines. He was preceded in death by his parents; his brothers, Alton Bean, Grady 'Toots' Bean and Johnnie Bean, Jr.

He was a member of the First Baptist Church of Amity, where he served as the Sunday School Superintendent for twenty-six years, and also served on the Housing Authority Board in Amity. Curt was a member of the Southern Lumbermans Association and the Arkansas Forestry Association. He was the founder of the Amity Angel Christmas for Kids and head of the Bean Team. Curt enjoyed going to the farm and raising cattle after his retirement, but his greatest joy in life was when he was spending time with his sweetie, family and his community. Funeral services will be held at 10:00 AM, Tuesday, July 27, 2021, in the Glenwood First Baptist Church with Bro. John McAnally and Bro. Larry Linam officiating.

TIMBER INDUSTRY

Weyerhaeuser is a name familiar in the area connected to the forestry and sawmill industry in Arkansas since 1956 when they began a sawmill in Arkansas. By 1969 they had acquired the Dierks Mill, a mill that had been operating since 1918. They began paper recycling in 1974. In 2004 the company planted 111 million trees, they reforest. They use the modern method of clear-cut to harvest. It allows sunlight to reach the newly planted seedlings. It results in stands of evenly-aged trees, requires fewer roads than selection harvest, is cost effective and efficient. They plan harvests to avoid breeding activities. They leave snags, logs and scattered live trees for the wildlife habitat. In 1834 Frederick Weyerhaeuser was born in Niedersaulheim, Germany, was known as the 'timber king'.

In Arkansas today, 2009, there is about 18.8 million acres of timberland mostly hardwood forest and hardwood-pine mixed forest where hardwood predominated, make up 73% of the total forest with the average pine plantation producing four tons per acre per year. The timber industry is the number one employer in south Arkansas. In the 18th century 9% of Arkansas was in forest. The Ouachita region had the short leaf pine and pine hardwood mixtures in drier sites. The settlers came and used the timber for homes, heating and other home and farmland uses. From 1887- 1909 Arkansas lumber production jumped twelve fold, railroads and sawmills were built. In 1909, 73% of all factory wage earners were employed by the lumber industry. Several mills closed after the 1920sand moved west. The Camden Paper and pulp Mill opened in 1928 by International Paper Company. A survey in 1929 found Arkansas devastated by the over-cutting but stated to recover in the 1930s. Companies started to replant and provide fire protection, selective logging and preservation of seed trees .The Arkansas Forestry Commission was established in 1930 to help preserve the forest. There was a growth in outdoor recreation Most of the timber land today is owned by individuals with less than one fifth of the forest in Arkansas as public. 17% of the forest is naturally seeded and 10% is in pure pine plantations in 1995.

In 2009 Arkansas is still the fourth largest producer of soft wood lumber in the States behind Oregon, Washington, California and Georgia. The timber industry is the logging sector, lumber /solid wood products, pulp and paper and furniture. Arkansas ships about $10 million annually in wood products. In 2009 only 32,000 are employed by the timber industry down from 44,000 ten years ago. Rain keeps loggers out of the woods but a logger still makes approximately $30,000. Land owners look for opportunities in "spot markets" e.g. by raising groves of ash and hickory.

MUSEUM EXHIBIT

The Montgomery County Heritage Museum. One of the first three focus areas will be logging activities / sawmills. The have a 3' photo of the pupils at the Mauldin school - all pupils unidentified. A story written by Julia E. Bigger about how Womble became a town includes a lot about the Caddo River Lumber Company has been donated to the museum. The Caddo River Lumber Company last holdings were sold in 1945.

DEEDS

Throughout the Montgomery County Courthouse Deed Books are hundreds of land transactions to the lumber companies. Deed books list the name of the purchaser (grantee) and the seller (grantor) also records the legal description of the land and the price paid.

A warranty deed is where the the grantor personally guarantees or warrants the title to be free of liens & encumbrances other than stated in the deed. The grantor convenants ( promises) to indemnity ( compensate) the grantee for any loss suffered because of the condition of the title other than disclosed encumbrances. The grantee will take the property free of any undisclosed claims of a third party.

Examples:

Deed: That we, R.T. Putman and M.G. Putman, is wife, for and in consideration of the sum of Two Hundred Dollars, to us in hand paid by Black Springs Lumber Company, a corporation organized under and by virtue of the laws of the State of Arkansas, the receipt of which is hereby acknowledged, do hereby grant, bargain and sell unto the said Black Springs Lumber Company, its successors and assigns, forever, all the pine timber which is standing, growing, lying or being on the following described lands.Warranty Deed: That Reinhold Wenzig, junior, joined by his wife, Lillian G. Wenzig, in consideration of the sum of One Thousand Eight Hundred and No/100 Dollars, in hand paid, the receipt of which is hereby acknowledged, hereby grant, bargain, sell and convey unto Black Springs Lumber Company, the following described real property and premises situated in Montgomery County, Arkansas, to wit; E�, NW� & SW� of the NW�. All section 5 & SE� if the NE� of section 6 in Township 3 South, of Range 23 West of the Fifth Principal Meridian, Arkansas, containing 158.17 acres. Signed and delivered this 12 day of October, 1923. Filed for record on this 15th day of November, 1923 Goerge [sic] Watkins, Clerk. [This land is three miles SE of Denby Point (as the crow flies) at the intersection of Forest Route 177 and W26 and East Fork Creek. Rienhardt N. Wenzig SR 1848-1911 is buried there and his grave, marked, is now Ouachita National Forest land. His son found him dead so with the help of a neighbor buried him. A graveside funeral service was held a week later.] The family came to the area in 1904 to Silver.

Old Forester, Scott Co.

We watched and listened to a solitary beautiful belted kingfisher (female) chattering away as it swooped down from tree to tree making her way around the Old Forester Mill pond.

When Mauldin closed the company town moved to Forester, in Scott Co. AR. The larger buildings were torn down but the smaller candy cane homes were moved to Forester. Old Forester as it is now known does not exist but the three acres Forester mill pond stands alone, lying calm amid the forest and hills, with a few concrete slabs visible. The pond has not been stocked with fish in years. Species present: Largemouth bass, sunfish and catfish. Located about a half mile south of Hwy 28 on the Old Forester Road (33). It is just of the west side of the road on a dime trail. Another way to get to it is if you have a pickup truck turn north on to the gravel Old Forester Road forest service road 33 on the top of Blowout Mountain on Hwy 270. To get there from the Pencil Bluff side, take Hwy 270 and at the top of Blowout Mountain (near Big Brushy Recreational Area) go 10.5 miles NE on forest rd 33, the road is in good condition, past f rd 888 and 136 on the left. Turn on 776 on the right, 1/8 mile to Old Forester Park. I hear there is an old grave just down 776. Someone was hung there. There is also an old cemetery a little bit further on down Rd 33 toward Parks and another 4-acre pond just down the road that branches off 33 at the intersection to the left. That was the water reservoir for Old Forester - gravity fed to the town. Only a 3-acre millpond, large concrete piles and slabs remain and a large Dr Carter Picnic Pavilion are at Old Forester Park. You can tell they had some heavy machinery there. In October (Sunday Oct. 6, 2002) there is an Old Forester Annual Reunion potluck dinner at the pavilion. "No speaker, just good visitin'." In 2009 the reunion was held on Sunday October 4th and contributions accepted for maintenance of park etc. and can be sent to Mrs Sarah Jo Parker, 2409 Queenbury Way, Port Smith, AR 72908. I hear the Oden Ranger station has some photos of Old Forester when it was a town population 1,306, 1940 census. There was a school, a gas, station, a movie theater, a church, hotel, doctor's office, and houses. The sawmill and the town were abandoned in 1952. It is advisable to take a along a national forest map, available from the Ranger stations, if you plan to drive around on the forest roads and don't were white if it is whitetail deer season.

The photograph of the work crew is courtesy of Sandy Fischer.

The man in the lower left Lionel R. HOWARD of Montgomery Co. AR. married 1899.

Forest Route 177, Owley Rd. SE of Mt Ida.A family tree can wither if nobody tends it.

REMEMBERING ARKANSAS : Arkansas' timber history

is rooted in pine forests by Tom W. Dillard

The Arkansas Democrat Gazette 1 December 2002 Stories by

Tom

Dillard

In 1939, the Arkansas General Assembly adopted a resolution declaring the "pine

tree" as the official state tree. The legislation does not specify which pine

species, so Arkansans must assume legislators were referring to the shortleaf

pine (Pinus echinata), the most commercially valuable of the pines found in the

state.

Of course, not all harvested timber was yellow pine. For many years the Arkansas

Ozarks produced most of the cedar lumber from which pencils were made. Walnut

trees were cut for furniture ; oaks provided lumber for everything from tool

handles to barrel staves. Big-time commercial timbering did not get under way in

Arkansas and the rest of the South until the exhaustion of the extensive Great

Lakes white pine forests in the late 1870s. Large sawmills then began popping up

all over Arkansas. Fordyce Lumber Co. began operations in 1888; the following

year A.H. Gates opened a large sawmill in Wilmar, Drew County. E.S. Crossett and

others founded the Crossett Lumber Co. in 1899, which owned timberlands in

Ashley County and Morehouse Parish, La. In Huttig, Union County, the Union Saw

Mill Co. operated soft and hardwood mills. These were large operations but

hundreds of smaller "peckerwood" sawmills were found throughout the state.

OUACHITA MOUNTAINS

After the turn of the century, lumbermen turned their attention to the Ouachita

Mountains of west-central Arkansas, an area full of shortleaf pine but plagued

with poor transportation and rugged terrain. In 1902, Herman Dierks moved to De

Queen to manage the family sawmill, the beginning of a huge lumber empire. Two

years later, the Fourche River Lumber Co. commenced operations on the eastern

edge of the Ouachitas in Perry County.

Among the more colorful lumbermen to cut the yellow pine forests of the

Ouachitas was Thomas W. Rosborough, who established the

Caddo River Lumber Co.

in Pike County in 1907. He was the brother-in-law of William N. Bemis, scion of

an old family of Prescott timber men and owners of the Ozan Lumber Co.

Rosborough created a company town, Rosboro, in northern Pike County near

Glenwood, to provide all the support needed by his sawmill. When local whites

objected to Rosborough's hiring black workers, the strong willed owner built a

wall around the black quarters and posted guards.

Rosborough pushed his logging operations deeply into the Ouachitas. He built a

large company town at Mauldin, in Montgomery County, where the buildings were

painted in bright red and white stripes. It was not long before the company town

had a larger population than Mount Ida, the county seat. In neighboring Scott

County, Rosborough established the sawmill town of Forester, which soon grew to

have schools, a theater, company stores and even a pharmacy. Many of these early

lumber operators practiced what became known as the "cut out and get out"

procedure, whereby they bought land cheaply, cut the timber, and then abandoned

the site.

By the end of the first decade of the 20th century it was clear that the old

system could not continue. In 1917 the Southern Pine Association, a powerful

industry group, sponsored a conference to discuss how timber companies could

dispose of their cutover lands. Gradually timber men came to realize that

forests could be managed to provide sustained harvesting. Sixty years ago the

first certified Arkansas Tree Farm was created in Dallas County, allowing

private citizens to engage in the sustained yield movement.

BUSINESS CONSOLIDATION

During the 1950s and '60s a great consolidation occurred in the lumber business,

with the Caddo Valley Lumber Co. being bought by Dierks, one of the pioneers in

sustained forest management. International Paper came on the scene and bought

vast tracts of forests, and in the 1950s opened its second paper mill in Pine

Bluff. Potlatch opened paper mills in Pine Bluff and McGehee. Georgia-Pacific

bought out the Crossett and Fordyce Lumber companies. Deltic Timber Corp.

acquired land from several struggling companies; some of the land in recent

years has been developed into upscale neighborhoods in far-western Little Rock.

The consolidation was essentially completed in 1969 when the giant Weyerhaeuser

Co. bought Dierks Forests Inc., just about the last of the large family-owned

timber firms. The Dierks sale included about 1.8 million acres of timberland in

Arkansas and Oklahoma, the largest family-controlled landholding in the nation.

Today only a few examples of virgin forest remain in Arkansas. The best example

of a surviving remnant of virgin shortleaf pine forest is the 400-acre Lake

Winona Research Natural Area, a National Park Service project in northwest

Saline County, where 250-year-old trees can still be seen.

REMEMBERING ARKANSAS: Company town seemed immune to worlds turmoil

Arkansas Democrat-Gazette August 17, 2008 Travel, Pages 89 By Tom Dillard

Last week I told you of a recent article in the Arkansas Historical Quarterly

about the early years of Crossett Lumber Co., the founding of the town of

Crossett, and the gradual transition from relying on railroads and trucks to

transport logs from the forests to the sawmill....

Nelson Examiner and New Zealand Chronicle,

9 September 1865, Page 3

" Fact, gentlemen," said a traveller who was giving a crowd of gaping listeners

an account of the strange things he had seen during his peregrinations in the

far West, " the trees are so close together in Arkansas that you may travel for

days together without finding them more than three feet apart ; and then the

game such vast numbers of buffalo, and bears, and wild cats, but in all the

world I never saw such deer!" " What of the deer?" asked a sharp-eyed

descendant of Nimrod. " Oh, the biggest, bouncing bucks you ever saw," was the

reply. " Why, my dear sir, the woods are perfectly alive with them, charging

about with great, branching horns full four feet apart." " Well, but if the

trees are only three feet apart, and the deer's horns four, I want you to tell

me how they get through ?" said Nimrod. " Oh, well, that's their look out," said

the traveller ; " I have nothing to do with that."

A

climate proxy:

Trees usually grow one ring a year. Wide rings denote wet weather. In a dry year

a narrow ring is produced. Tree ring data can be retrieved from original timbers

found in historic structure, and cross sections from dead logs. Log cabin

at the museum.

The log below had approx. 100 rings.

Though man can make a poem, "only God can

make a tree."

Rex Mann.

![]()

Arkansas Democrat Gazette

Sawmill's revival gives Arkansas town a lift. Hurt by plant's closure,

Glenwood now sees jobs return

by Stephen Steed | June 1, 2017

GLENWOOD -- A sawmill has reopened in Glenwood nearly seven years after being

shuttered, providing an economic boost to a town of 2,500 hard on the banks of

the Caddo River and nestled in a valley of the Ouachita Mountains. When word of

the mill's imminent reopening spread a year ago, Caddo River Forest Products

received more than 300 applications for the first 100 jobs, Brett Bray, the

plant's general manager, said recently. "This is a boon not just for Glenwood

and Pike County but for towns in three neighboring counties."

The owners and employees of Caddo River Forest Products are

scheduled to meet Gov. Asa Hutchinson and various town, county and economic

development leaders and elected officials in a ceremony at the plant today.

With a skeleton crew of supervisors and maintenance workers, the sawmill

actually "powered up" on May 15 and, within a few hours, produced its first

lumber since 2010, Bray said. "I really expected a much harder start-up for a

mill that had been closed for so long," Bray said. "We went through things we

knew had to be fixed, and we decided just to wait and see what happened at

start-up. All things considered, it went very smoothly." Logging trucks have

been arriving at the sawmill for weeks, each depositing 29.2 tons of yellow

pine. Some 12,000 tons of logs are ready for production at the mill's 111 acres,

Bray said.

The mill has hired 103 workers so far, for 10-hour shifts four days a week. A

second shift will be added next spring, increasing employment to about 150, with

more hires coming as needed, Bray said. The company believes another 300 jobs

will be created in supporting industries, such as trucking.

Annual payroll is estimated at $4 million. The mill has hired

103 workers so far, for 10-hour shifts four days a week. A second shift will be

added next spring, increasing employment to about 150, with more hires coming as

needed, Bray said. The company believes another 300 jobs will be created in

supporting industries, such as trucking.

Annual payroll is estimated at $4 million. When company officials announced

their plans a year ago, they said $50 million would be invested. Bray, a 28-year

veteran of the timber and logging industry, put the average wage at $16 an hour.

"Skilled craftsmen" -- the millwrights, electricians and those who keep the saws

sharp -- "make very competitive wages, and that's all I can say about that," he

said. The mill's top 10 supervisors average 32 years of experience in the

industry, Bray said, and he brought two of them out of retirement. "One of the

best days of my life," Jim Tweedle, a Glenwood native and one of those former

retirees, said of getting a telephone call about going back to work. Tweedle

started working at the mill after it was built by Georgia-Pacific Corp. in 1974,

and he stayed there through the 26 years, from 1984 to 2010, when it was owned

by a pioneer family of Pike County, the Beans. The Curt Bean Lumber Co. closed

in November 2010, partly because of the recession and its effect on housing

construction. Tweedle was among 200 workers who lost their jobs at what had been

the town's largest employer. "I like this much better than retirement," Tweedle,

now the supervisor of the drying and shipping portions of the mill, said.

Growth in Glenwood came to a halt after Bean closed its doors

and filed for bankruptcy in late 2010, Tweedle said. "We certainly didn't see

the growth we had been seeing for 10 years," he said.

While some of his co-workers moved away, many others commuted to jobs in

Arkadelphia and Hot Springs, Tweedle said. Richard Scott of Norman in Montgomery

County, about a dozen miles north of Glenwood, worked at the sawmill from 1980

until its closing. For several years, he commuted to a job in Mansfield in

Sebastian County -- a drive of 1 hours, one way, every day. Like Tweedle, Scott

was hired in early 2016 to help restart the mill. "You could feel the excitement

in town," he said. "With it closed for so long, people just didn't think it

would be cranked back up again." Tweedle and Scott credit the Caddo River --

with its always-popular canoe and kayak rentals, campgrounds and cabins -- with

keeping the town alive.

Downtown Glenwood -- a three-block stretch lining both sides

of Broadway, the town's main drag -- is about a mile south of the mill. An empty

storefront is hard to find. Susie Cantrell is an expert on the comings and

goings on Broadway: She was born there, in a doctor's office in the back of the

still-standing Woodard's Drug Store. She can tick off a list of businesses that

have opened on Broadway the past couple of years, including the Bainum Library

and Learning Center, Angel's Attic & Flea Market, and Master's Touch Graphics.

There's plenty of foot traffic, too, in and out of Plyler's Home Center and

Wright's supermarket, which have been two of Glenwood's business anchors for

decades.

City Cafe reopened just three weeks ago, in part because of the sawmill's

rebirth, said Cantrell, the cafe's manager and chief cook and the owner of the

building that houses the business. Cantrell owned and operated the cafe from

2004-12. The closing of Bean Lumber "hurt us tremendously," she said. "It had a

horrible impact on the economy, and it trickled on down the food chain, to my

cafe, to the grocery stores, to the gas stations, to the insurance agents."

While Bean's closing hurt, it was an illness in the family that forced her to

shut down the cafe for several years, she said. The mill's revival, though,

played a part in its reopening, she said, hoping a $7.99 buffet is attractive to

sawmill workers with 30-minute lunch breaks.

A few doors down, Debbie Herrell attends to business at

Billy's House of Guitars & Musical Museum, an eclectic place that is as much a

museum as it is a retail store. Her late husband, Billy Herrell, opened the shop

on Broadway in 1995, after a couple of decades of collecting and buying, and he

built a recording studio, too.

Herrell died in January 2014 after a short illness, at age 56. Debbie Herrell

struggled with whether to take over the business.

The sawmill's closing hurt every business in town, she said recently. Rumors of

its revival circulated for years, only to be shot down, she recalled. "It's nice

to have a little good news in Glenwood," she said.

Caddo River Forest Products is a consortium of investors,

including Florida-based Suwannee Lumber Co., Texas-based Castle Hill Partners

and McCaslin Barrow Henderson, and Blue Wolf Capital Partners in New York.

The effort to reopen the mill began more than three years ago, and the project

is eligible for various economic development incentives from the state. Those

incentives include about $400,000 in sales-tax rebates and $800,000 in rebates

regarding payroll, once certain job-creation goals are met.

Federal grants will go to reopening a long-defunct stretch of

a short-line railroad that served the mill and other timber-related industries

for decades.

Bray said the new company has spent millions on new equipment, including a laser

that scans every log, grades it and determines its best cut and use, and on

repairing what could be fixed. "Old sawmill equipment left behind like this is

basically steel and rusted chains," he said. "You can replace it for $100,000 or

fix it for $60,000." Bray said Caddo River Forest Products will work hard at

being part of the community.

"We want our name on the scoreboards at the baseball fields and on the back of

kids' jerseys," he said. "One of our goals was to bring the [former] Bean

employees back home. We've done that. Now, if they're happy at home, they're

going to be happy at the mill."

Magonlia Reporter.com

Conifex acquires sawmills in Glenwood and Florida

May 16, 2018

VANCOUVER, British Columbia, Canada -- Conifex Timber Inc. said Wednesday that

it is buying from BW SLC Holdings, LLC, an affiliate of Blue Wolf Capital

Partners LLC and the minority shareholders of Caddo River Forest Products, LLC

all of the outstanding membership interests of Suwannee Lumber Holding Company,

LLC, Suwannee Timber Management, LLC and Caddo River Forest Products, LLC.

The Caddo River sawmill in Glenwood and the Suwannee sawmill in Cross City, FL

both primarily produce Southern yellow pine softwood lumber and specialty

products like decking. The Caddo River mill and the Suwannee mill each have an

annual dimension lumber capacity of approximately 185 million board feet on a

two-shift basis. As a result of this transaction, Conifex's annual lumber

production capacity will increase by approximately 50 percent to 1.1 billion

board feet while its dimension lumber platform in the Southern U.S. will

increase by 200 percent to approximately 550 million board feet, representing

approximately 50 percent of the company's total pro forma lumber capacity. The

mills will add premium priced SYP decking products to Conifex's current product

mix, along with long established customer relationships in Florida and the

Southern and Eastern U.S. Both mills have had significant modernization projects

completed in recent years. Most recently, a $12 million modernization project

was completed at the Suwannee Mill in 2017 and approximately $14 million of

capital expenditures were completed at the Caddo River Mill in connection with

its re-start in May 2017. Conifex estimates that integrating the acquired mills

with its existing operations will generate over $5 million in synergies through

procurement opportunities, cost benefits, customer service rationalization, and

providing business support services to an expanded number of mill locations.

Conifex believes these annual run-rate benefits will be achieved within 12

months of closing the transaction. Ken Shields, Conifex's president and CEO,

said, This is a highly strategic and transformative transaction for Conifex. It

brings together two successful growth-oriented companies to create a leading SYP

lumber producer. The Suwannee and Caddo River mills significantly increase our

presence in the U.S. South, which we have identified as an important strategic

area with proximity to high quality and abundant fibre supply in addition to

some of North America's fastest growing population centres and housing markets.

The Suwannee and Caddo River mills' culture and operations provide an ideal fit

to increase our profitability and provide a launching pad to scale our business

and compete with the best sawmills in North America. We are also well positioned

to realize upon the ramp up in production at the Caddo River mill and our El

Dorado mill during the balance of 2018 and next year.

Conifex's consideration for its acquisition of the BW Group consists of $150

million plus the net working capital of the BW Group at closing in cash, the

value of $50 million through the issuance of common shares of Conifex with an

issue price of $6.50 per share, 3.5 million warrants to purchase common shares

for a period of five years after closing of the acquisition, at an exercise

price of $8.78 per share. Charles P. Miller and George R. Judd shall be

appointed to Conifex's Board of Directors on the closing of the transaction.

Miller is a partner at Blue Wolf and Judd is a strategic advisor to Blue Wolf

and a member of BW SLC's board. Previously, Judd served as the chief executive

officer of PrimeSource Building Products, Inc., one of the largest purveyors of

fasteners and distributors of building materials. Conifex has received from a

U.S. bank a commitment for a new credit facility in the amount of $220 million

with a term of five years to partially finance the acquisition, replace its

current facility and for general working capital. Conifex is also reviewing

other supplemental funding for the acquisition.

A young woodsman sharpening a vintage crosscut saw. The photo was taken by photographer Bluford W. Muir in August 1938. This woodsman was working for the Waldron Lumber Company in the Ouachita National Forest.

Crosscut blades are either curved or straight backs, but the toothed edge is always convex (bulging) and this is what differs them from pit saws which the toothed edge is always straight. Vintage saws, older than 30 years, can bend easily and can be folded end-to-end for carrying on one's back. Modern saws are typically stamped out of sheet metal and are manufactured from contemporary alloys; they behave very differently from vintage saws, which have historically been made by craftsmen who understood the nuances of the saws they produced.

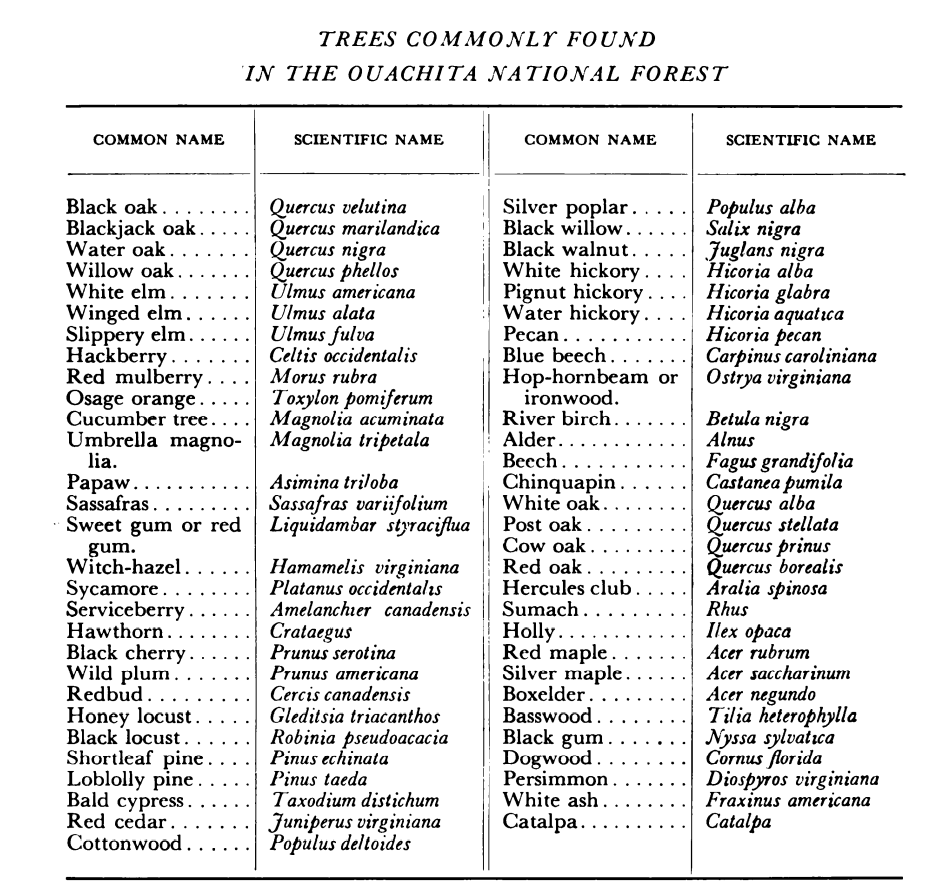

ONF 1939 booklet Trees commonly found in the Ouachita National Forest.

Lantern from logging line